Flexible Packaging (Lamination Film)

Safe sealing for your products

Industrial Packaging (Protection Film)

Protection packaging for your products

Construction Materials

High quality contraction materials

“Trust in business relationships is earned not by supporting customers in good times, but by standing firmly with them during the rainy days”

Firas Barakat

Managing Director

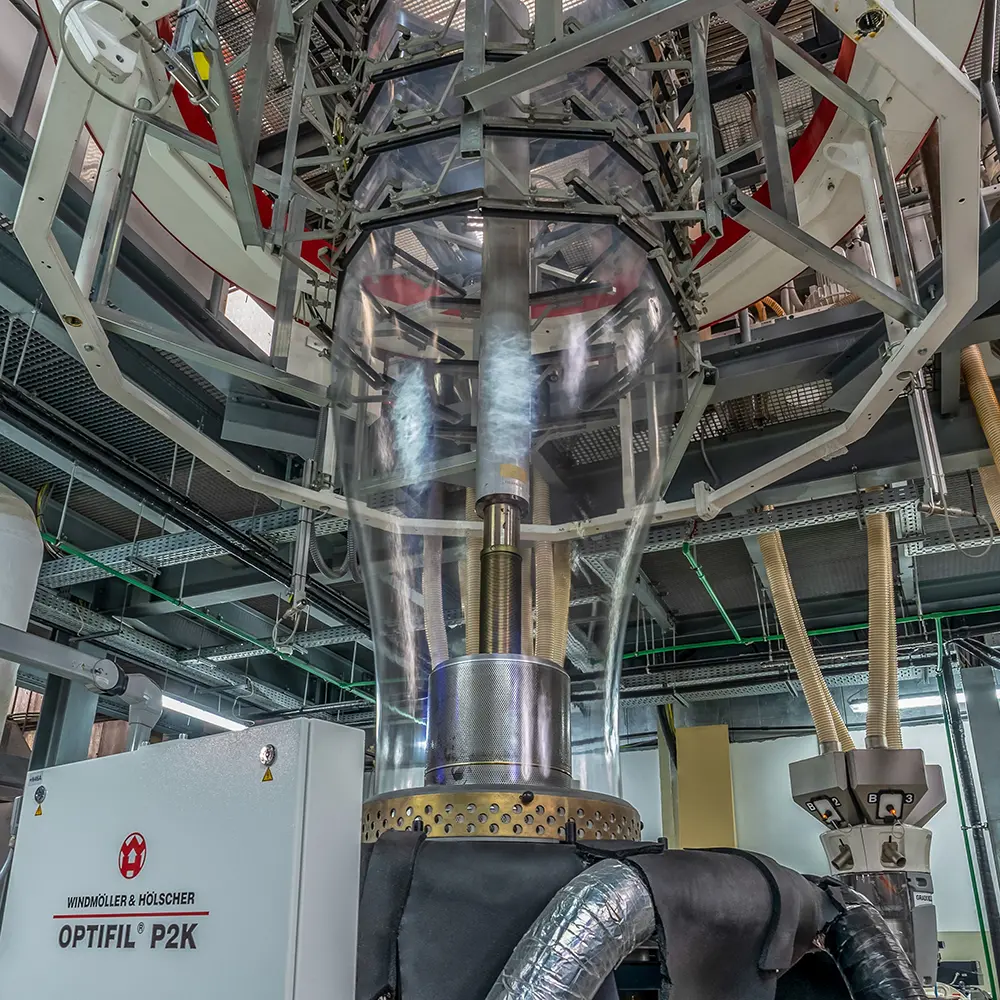

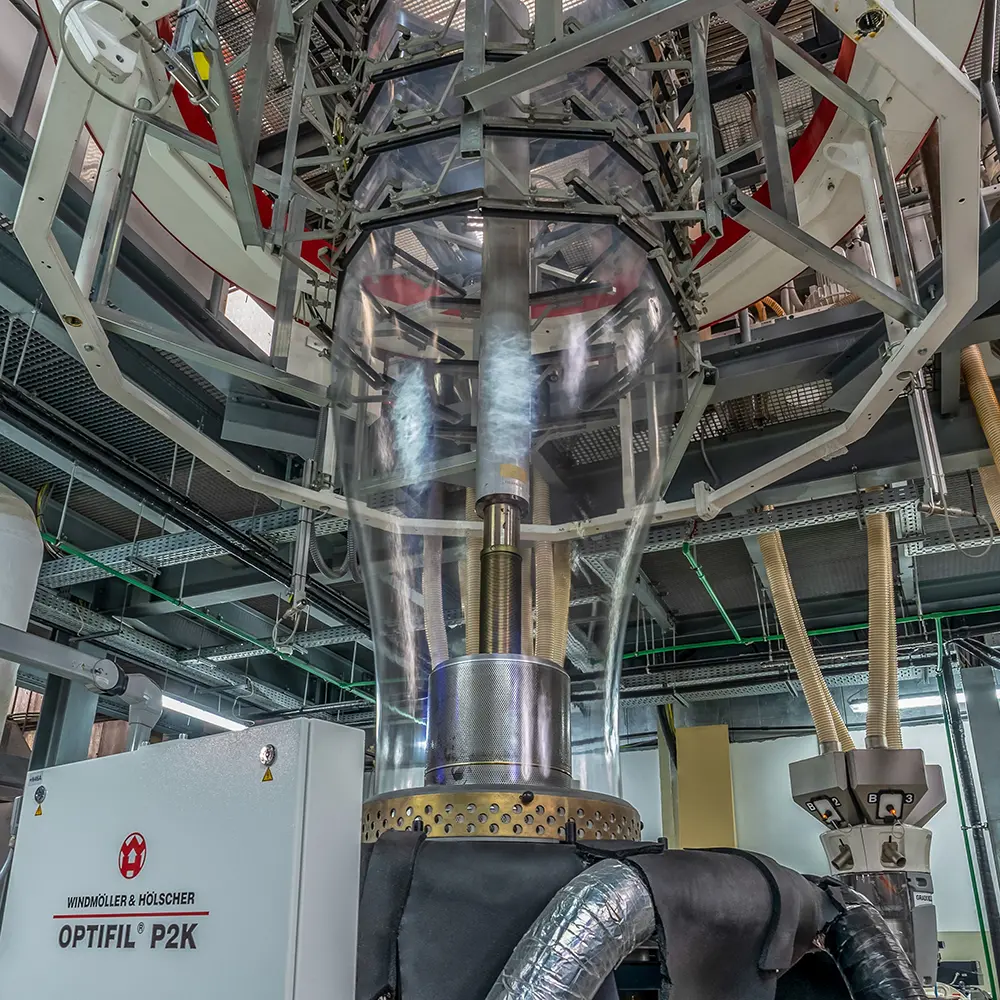

Leading Manufacturer of Lamination Grade Polyethylene Films

Ashkal means variety, taking shape, and evolving forms. For those who say what’s in a name? We say it’s a source, from where we derive our business strategy and inspiration to run our relationships with suppliers and customers alike.

2 Decades of Manufacturing Excellence

Marching ahead with close collaboration of our partners and clients, combining in depth industry knowledge, decades of experience, ingenuity and adaptability to deliver excellence

Quality & Cost-Effectiveness

Customer Service

Quality Service

Client Satisfaction

VISION

Continuously evolve the business and take shape with the changing times by remaining customer-centric and geared up to offer consultative solutions to their business/value chain challenges.

MISSION

Build a business in Polymer processing and construction materials, that is ranked No 1 by our customers and suppliers on trust in doing business and for displaying a sense of urgency in addressing their business situations.

Values

Trust: We will earn yours.

Quality: It’s on top of our mind. Always..

Commitment: It’s an assurance – we will

always live through it.

Key Strength

• Satisfied Customers.

• Reliable Suppliers.

• Committed Employees.

• Culture of Safety, Innovation &

Entrepreneurship.

80 customers in 10 countries

“We always ensure that we are providing our customers with highest quality products through intensive R&D, health and safety measures, quality control and feedback mechanisms”

– Firas Barakat.

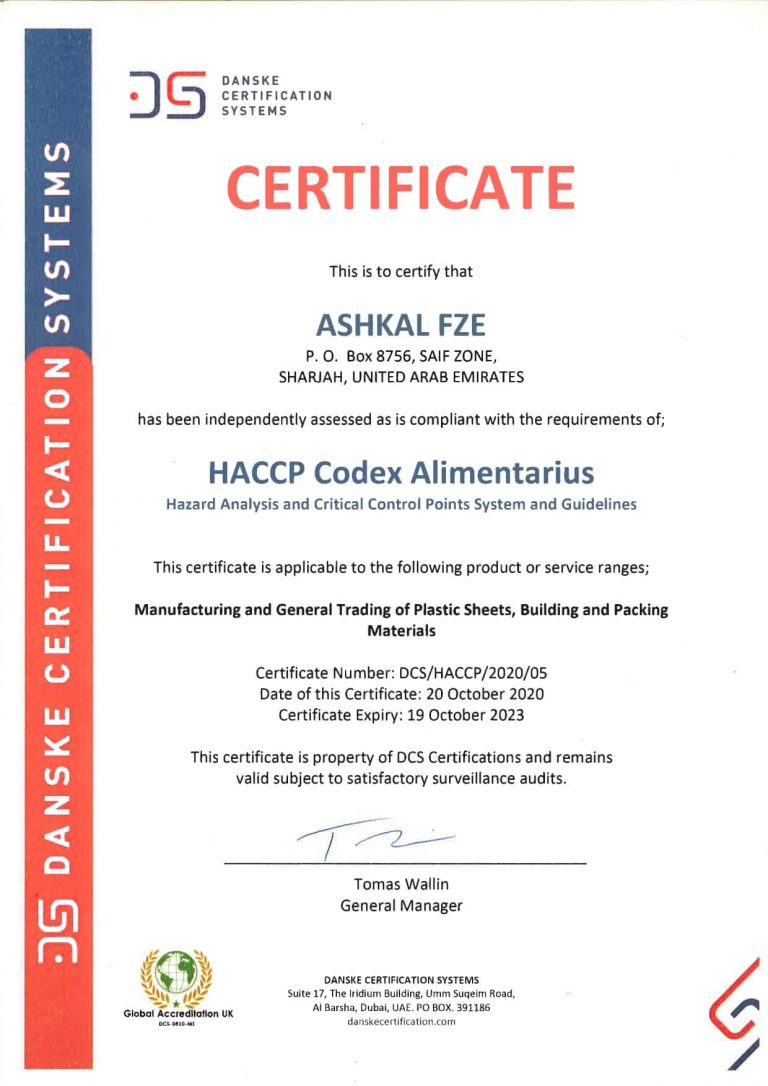

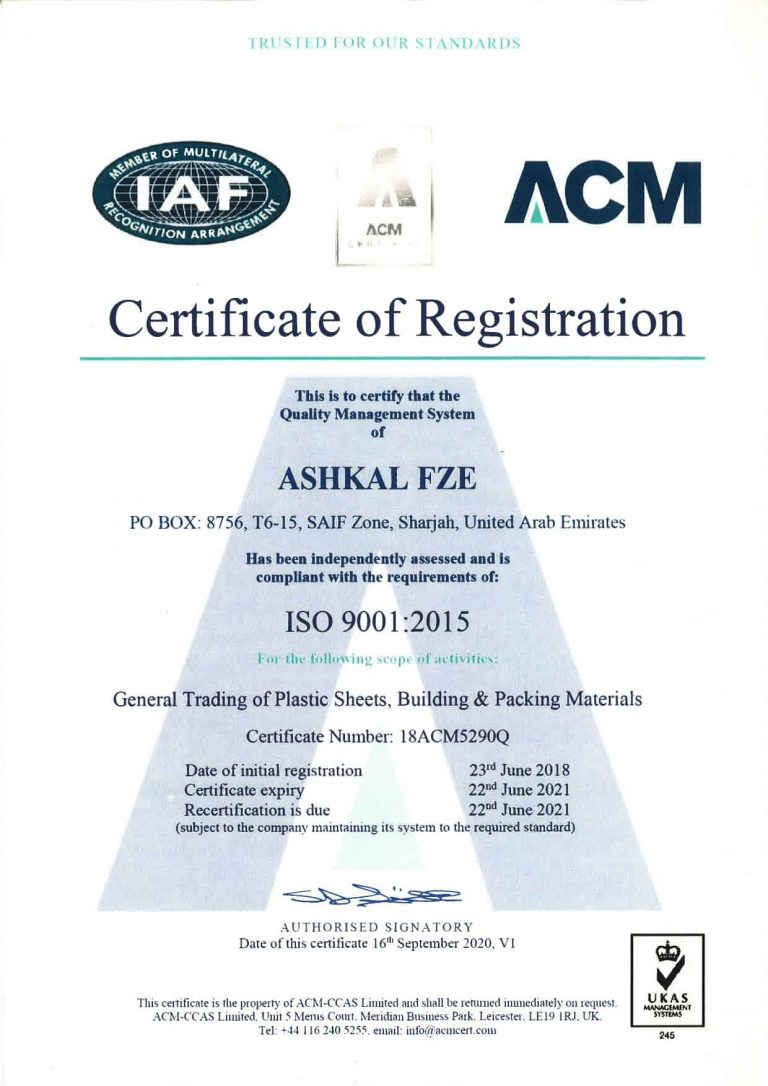

QUALITY CONTROL & ASSURANCE

It’s a way of life here at Ashkal. We simply transfer the solid trust we have in our process and products to our customers.

Quality Matters To Us